Nexa3D Further Expands its Resin Portfolio with the Release of Ceramic, Flexible, and Clear Materials

A growing resin portfolio now includes over 20 validated photopolymer materials for both the NXE series and the XiP printer platforms

Company worked with material experts at BASF and Henkel to validate custom formulations for its ultrafast fleet of industrial and desktop 3D printers

VENTURA, Calif.–(BUSINESS WIRE)–#additivemanufacturing–Nexa3D, the leading maker of ultrafast professional and industrial polymer 3D printers, today announced the expansion of its high-performance functional resin portfolio, with the immediate commercial availability of three new photopolymer resins tailored to address the growing demand for its ultrafast industrial and desktop 3D printers.

“The addition of three new resins reaffirms our commitment to collaborating with industry’s material experts to continue to formulate and validate high-performing resins that will further expand customer applications that are benefiting from our ultrafast 3D printing technology,” said Kevin McAlea, Chief Operating Officer at Nexa3D. “Our expanding range of printers and materials presents a significant upgrade for traditional stereolithography and DLP users with its ultrafast printing speed, high volume precision, and broad range of performance materials that come at the most economical cost of ownership available on the market today.”

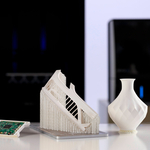

xCERAMIC3280

The company worked with material experts at BASF to validate the new ceramic composite resin, xCERAMIC3280, as a fast printing, rigid material with high heat deflection temperature and excellent tensile modulus. The new xCERAMIC3280 resin is a perfect choice for tooling applications as well as wind tunnel testing models.

xMODEL17-Clear

Through its collaboration with material experts at Henkel, the company announced immediate availability of xMODEL17-Clear, a rigid and durable modeling material with enhanced clarity, perfect for prototyping applications that require fine feature details and high-quality translucent or transparent surface finishes.

xFLEX402

The company also released xFLEX402, a flexible material with firmer shore 76A durometer, high elongation at break and excellent tensile strength, ideal for functional prototyping applications of elastomeric components and production parts.

The company is showcasing all three new materials at this week’s Formnext, Hall 11.1 | Booth E31. To learn more about the new materials please see the media kit or material selector page.

About Nexa3D

Nexa3D is passionate about digitizing supply chains sustainably. The company makes ultrafast polymer 3D printers that deliver up to 20x productivity gains to professionals and businesses of all sizes. Partnerships with world-class material suppliers and its open materials platform unlock the full potential of additively manufactured polymers for volume production. Automated software tools optimize the entire production cycle using process interplay algorithms that ensure part performance and production consistency, while reducing waste, energy, and minimizing carbon footprint.

For more information on Nexa3D and its products, visit the Nexa3D website, or connect socially on LinkedIn, Twitter, Facebook, and Instagram.

Contacts

Nina SwientonChief Marketing Officer

nina.swienton@nexa3d.com